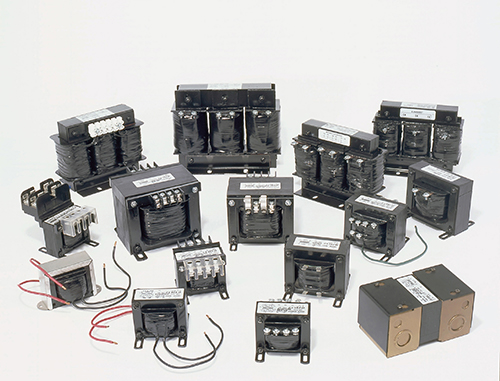

Our History

We’ve been making energy efficient electrical transformers with the best prices for over 50 years.

For over 60 years of manufacturing a wide range of transformers and three generations of ownership, our philosophy has not changed. Our goal at Marcus has always been to provide the customer with the highest quality products and the best service in the industry. We know that there are no shortcuts to achieving this goal.

Marcus proved to become an industry leader in the United States and Canada, manufacturing top quality electrical transformers. Among our notable achievements are new insulation materials to increase transformer life, unique magnetic cores to reduce sound levels, and over 40 percent annual energy savings compared to competitive makes. Today, our patented WATT+ PLUS TM technology which incorporates only pure electrolytic copper coil windings, is recognized as the new standard of power for the electrical transformer industry. This Marcus technology recovers the original cost of the transformer within a period of 5 years. Most importantly, energy consumption over a 24 hour period is comparable to utility grade pole mounted transformers.

We’re proud of the reputation we’ve earned for manufacturing quality products that deliver exceptional performance and savings. No other transformer outperforms a Marcus transformer. We Guarantee it.

Marcus Advanced WATT+ PLUS TM Technology

Maximum efficiency, lowest losses, trouble-free performance, longer life Long before the term ‘Green Energy’ came into vogue, we were making lighting and distribution transformers that significantly reduced power consumption for commercial and industrial users. Marcus advanced WATT+ PLUS manufacturing technology ensures maximum efficiency, lowest losses, trouble-free performance, and longer transformer life.

Features

Read more about Marcus Watt+PlusTM Technology [pdf, 287kb]

Our Unique Wound Core Construction for Minimum Power Loss

The unique oval shape of Marcus wound core construction, unlike other conventional transformers core construction, ensures that the flow of magnetic flux is carried in the direction of cold-rolled grain-oriented steel for minimal core loss.

Copper Windings for Maximum Efficiency

Marcus coils are wound with 100% pure electrolytic high conductivity copper for long, trouble-free transformer life and a less expensive life cycle.

Although more expensive, copper is the best electrical conductor. Copper wound transformers don’t heat up so quickly, are more corrosion resistant and are easier to install than their aluminum equivalents, rendering them highly efficient with lower operating costs.

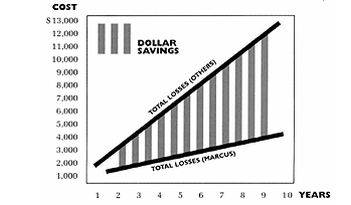

More Power at Less Cost

Marcus combined unique core design, copper windings, and new insulation material to ensure maximum electrical energy efficiency and reduced electricity bills, leading to a faster payback period. Marcus transformers will guarantee over 40 percent annual energy savings compared to competitive makes.

Easily Accessible Terminal Board

Voltages are clearly labeled to facilitate trouble-free connecting of line and load cables. All coil leads are directly brazed to terminal board studs to prevent heating and loosening.

Designed for Cooler Running

Marcus distribution transformers are manufactured with heatproof Class 220° C materials only and designed to operate well below the maximum allowable temperature of rise of 150° C.

More Effective Heat Transfer

To provide effective heat transfer, all our core and coil assemblies are double dipped in solvent-less, non-hygroscopic resin and baked thoroughly.

Quieter Operation

Anti-vibration isolators between the element and enclosure reduce vibration transfer to the surrounding structure, ensuring quieter operation.

Further Exceptional Quality Features

- Distribution transformers taps are all fastened to the primary terminal board and clearly labeled to enable fast and easy voltage adjustments (same point as last box “Easily Accessible Terminal Board”?)

- Wall and/or floor channels are included as standard accessories

- Dry-type transformers have integral anti-vibration cushions to reduce structural vibration transfer

- Industrial control transformers are bobbin-wound to facilitate heat transfer

- Control terminals are robustly anchored to eliminate flexing or breakage

- Control designs ensure nominal voltage accuracy under operating loads

Quality Control from Start to Finish

Only the highest quality materials are ever used in all our products. Every component in a Marcus transformer is made with strict quality control and is thoroughly tested during manufacture assembly and upon completion. Each unit must meet our rigid inspection and test requirements before it is shipped.

ll Marcus products utilize the most modern automated manufacturing facilities available. Our trained and experienced staff ensures that the highest quality criterion is maintained at all our facilities. We are dedicated to the highest level of service and quality at competitive prices.

Meeting Standard Agency Approval:

Marcus Transformer models meet the following agency standards (where applicable): UL, CSA, CUL, CE.

Testing Procedures and Certifications

Material Quality Assurance

Purchasing:

Marcus strives to ensure that there are several suppliers for each material required in production. This avoids unanticipated shipping delays and customer inconvenience. Whenever possible, local or domestic suppliers are preferred to avoid the complication of long supply chains and delays. Furthermore, face-to-face meetings promote better communications, understanding and accountability. All materials must be UL/CSA listed.

Receiving:

When materials are received, close inspection reveals any packaging problems and damage such as water infiltration. This is especially important with insulation materials. Sample lots of magnetic wire and core steel are tested to ensure the material meets our high quality standards.

Storage:

Although companies favor a just-in-time material flow, in reality there is always a period during which production raw materials must be stored. At Marcus, we make certain that all goods received are stored in a clean and dry location to prevent any damage or deterioration.

Excellent Customer Care

As a family-owned concern, we take great pride in treating our customers with the respect and attention they rightfully deserve. We’re big enough to look after all your electrical transformer requirements, yet small enough to care.

We carefully train our sales staff to help our customers choose the proper transformer for their application and help guide them through the order process. When engineering technical support is required, our highly qualified technical support group is there to help.

Reliable. Competitive. Custom.

We provide custom products for special “sensitive” applications

such as extra quite, lowest temperature rise, low impedance, smallest footprint, etc.